BRUNITEC - Tools and Honing Machines

Estados Unidos Street, 1250 - Guaraú - Salto-SP-Brazil

☎ CALL: +55 (11) 4028-9944

Honing

What is the honing process?

Honing is an abrasion machining process used in holes to correct problems such as:

- Bore diameter;

- Internal bore geometry (cylindricity and circularity);

- Finishing of the machined surface (angle of crossing of scratches and roughness);

- Alignment between bores.

It is a process of high precision and quick removal of material, which can be realized in different types of materials, such as cast iron, tempered steel, soft steel, bronze, brass, hard chrome, ceramic, and aluminum, among many others.

The honing is made through four main components: Honing machine, lubricating oil, honing tool and super abrasive diamond or CBN (Borazon) stones.

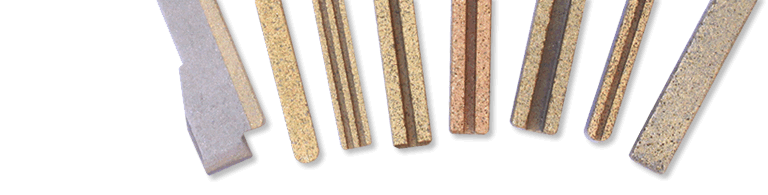

The super abrasive honing stones are manufactured with a metal alloy and with the type of grain specified to honing each type of material, which in contact with the work surface, make the removal by abrasion and reach the specified finishing. The super abrasives (diamonds or CBN) have high abrasive resistance and thermal conductivity, which allows working with high cutting speed and various contact pressures, providing gains in productivity, durability and quality in the grinding process.

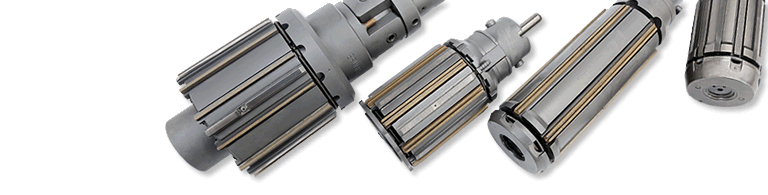

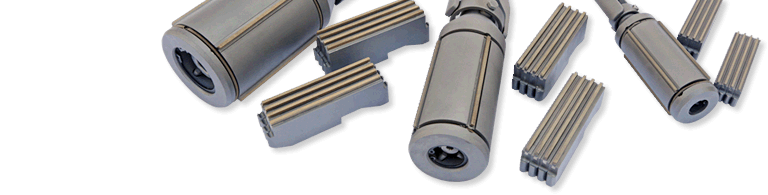

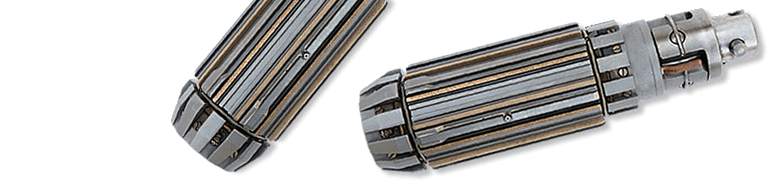

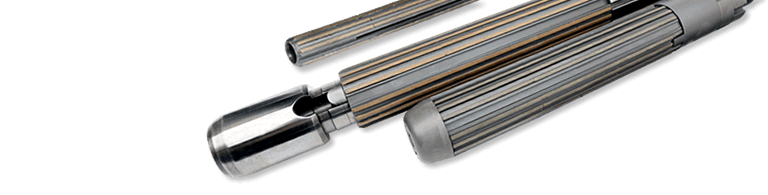

The honing tools (mandrel) are manufactured according to the diameter and type of the product to be machined. They have expansive supports in which the honing stones are allocated. As the supports expand, the honing stones come into contact with the product and begin to remove the material.

The honing machine is where the honing tool is fixed and its main functions are: Expand the tool when necessary, provide axial and radial movement to it and cool and lubricate the honing process with the specific oil for each type of material to be machined.

BRUNITEC Speed and Flexibility.

Tell Us Your Need